Let's get to know industrial valves (and industrial fittings) better

Industrial valves They are used to guide fluid flows such as liquids, gases, or pastes in manufacturing and factories. Industrial valves and fittings are one of the most .important components of any factory that produces raw materials. And you can see a smaller example of it in the piping of residential houses. that of connections They are used to disconnect and connect the water flow of the building. Next, in this article, while introducing the history of faucets, we will try to tell you about different examples and important things in the better choice of this tool. .

History of industrial valves and fittings

The history of human use of pipes and fittings to direct the flow of fluid goes back to 700 BC, when clay or metal was used for this purpose, and after some time, lead, silver and marble took the place of clay.

In 1937, a student proposed for the first time the use of a valve to control the amount of water entering or exiting and also to control its temperature. Before that, two separate pipes were used for cold or hot flow, in which the water temperature.of each pipe was extremely high or low. .

After presenting the prototype, this model of faucets was not welcomed. And after making changes in it in 1940, a sample of today’s faucets was presented to the market and consumers could mix two hot and cold water with each other to reach the ideal temperature.

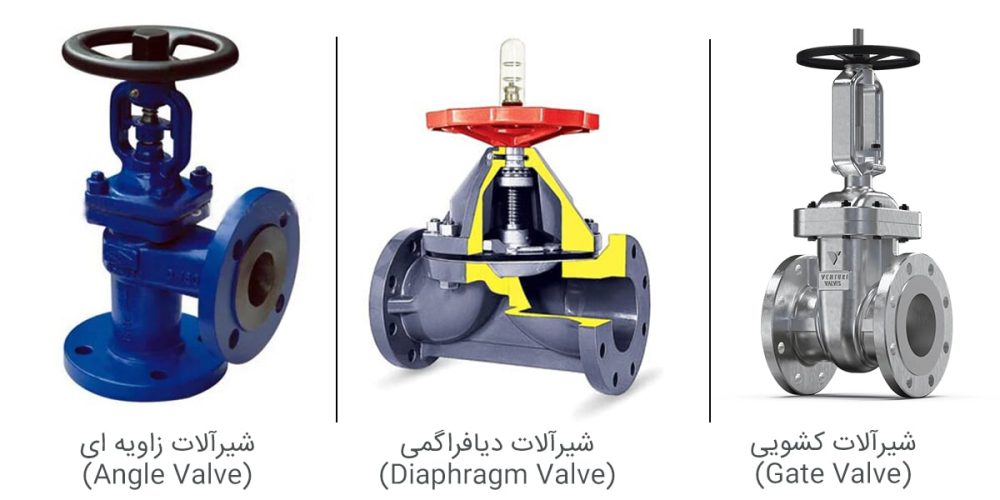

All types of valves and industrial fittings

In the following, we will introduce the types of valves and industrial fittings:

Ball valves

The design of this type of industrial valves and fittings is in such a way that the path of the fluid changes up to 180 degrees, and as a result, we will see a large pressure drop for the fluid during discharge or displacement. In this model of valves, the possibility of cavitation or ram impact increases .

Needle valves

In this model, the valves have a very accurate and high performance. They are used in pipes with a small diameter and thickness, and they can measure the movement of the fluid accurately and completely. This model is mostly used for laboratories and systems that require precise instruments .

Ball valves

This type of faucet has a spherical ball that makes a 90-degree turn at the flow passage, blocking the fluid path, which is mainly used to control and pipe the flow of hot and cold water..

Sliding valves

This model of industrial valves and fittings is used for complete blockage or complete opening of the fluid flow in pipes, and in them, unlike ball valves, there is less pressure drop on the transfer flow..

Diaphragm valves

In this model, the valves have a very accurate and high performance. And in pipes with a diameter and thickness ofand they can measure the movement of the fluid accurately and completely. This model is mostly used for laboratories and systems that require precise instruments. .

In this model, by using a plastic piece that has a high elasticity, other parts of the valve are separated from the fluid flow and an obstacle is created for the collision and connection of the passing flow with the valve body. This model is mostly used to transfer acidic currents .

Angular valves

In fact, this model is a type of spherical valve, in which the fluid flow changes direction up to 90 degrees, and we see a lower pressure drop than the spherical model..

Types and materials of industrial valves

The first and most important point when choosing industrial valves should be attention to the type and raw materials that make them up. Industrial fittings and valves are usually made of carbon steel, Inconel, Hastelloy, Duplex, Monel, stainless steel, carbon steel, cast iron, Stellite and … if the materials passing through them have acidic properties, it is better to use materials that show more resistance against corrosion and vulnerability.

Map of facilities and piping

Before buying, it is better to consider the location of the support for the pipes as well as their expansion and contraction in different environmental and temperature conditions according to the plan of the facilities and piping, and prepare the best options according to these items..

How the valve works

Paying attention to the opening and closing of the valve, and considering the amount of its rotation angle to transfer and direct the fluid flow, is one of the important and main points for choosing industrial valves and fittings..

Flow rate of industrial valves

The flow rate through the valves determines .the maximum and minimum fluid flow through the valve and determines the pressure drop of the flow through the valve. Before buying, be sure to match the volume of the faucet you want with the volume of the used pipes .

The operating temperature of the valve

Sometimes the temperature of the fluid passing through the pipes is very high, and industrial valves and fittings are used to control and guide it. If there are materials with this property in the desired location, it is better to choose a tool that is more resistant to high temperature .

Map of facilities and piping

The reduction of fluid pressure is due to the friction in the walls of the pipes and the presence of connections and valves in the fluid movement path. The presence of valves has caused secondary drops, which are tried to compensate for this pressure drop with a pump or compressor. Of course, sometimes the pressure drop is not compensated and fluid movement becomes problematic.

For more information or to get industrial valves, click here with TAPCO experts.